Additional Facilities at ARL:UT

Acoustic Testing

Our onsite acoustic testing facilities allow researchers to save project time and funding by finding design or manufacture defects before full scale sea trials. For high frequency calibration and testing, an indoor sonar model tank offers a test space 12 feet deep, 15 feet wide and 60 feet long.

Outside, ARL:UT uses a large cedar tank, 38 feet deep by 55 feet in diameter, that holds about 700,000 gallons of filtered, ambient temperature water. The outdoor tank is accessible from the precision machining facility via a 15-ton overhead bridge crane, and has been used for a variety of purposes, from acoustic testing to the evaluation of large subsea research equipment.

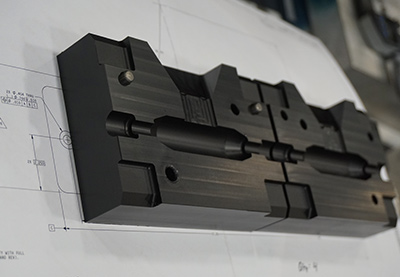

Precision Machining

ARL:UT’s machinists use precision machining technology to import solid models directly from designers. Our machinists develop designs collaboratively from sketches as well as produce parts from traditional drawings. Equipment available includes multiple four-axis machining centers (CNC turret lathe and milling machines); manual mills, lathes and presses; a coordinate measurement machine that helps verify dimensional accuracy of parts; and comprehensive welding capabilities including tungsten inert gas, stick, and chamber welding.

JMH LTTS

The John M. Huckabay Lake Travis Test Station, located near Mansfield Dam, is a specialized facility capable of year-round testing and underwater acoustics research. A research dive team operates in the waters of the JMH LTTS, supports the outdoor test tank, and travels around the world for ARL:UT at-sea operations. JMH LTTS includes three large buildings, research and support vessels, and a 2,500 square foot auxiliary barge for testing and calibrating heavy equipment.

JMH LTTS floats in 60-90 feet of water and is anchored with electric hoists that allow adjustments based on lake levels. Here, researchers complete rigorous simulated at-sea and other testing of equipment and systems. This enhances our ability to provide durable, working prototypes and is key to providing timely, efficient, and successful on-site installation of systems and equipment.